The manner in which the process makes use of the various physical properties that aluminum possesses is one of the aspects that is among the most innovative and forward-thinking aspects of the process.

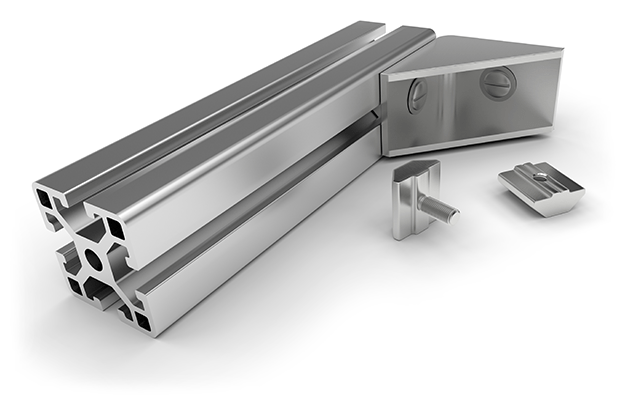

The process that is utilized during the manufacturing of aluminum extrusions in order to create the product.

The process of extruding aluminum is also known as the bulk plastic deformation process in certain circles. This name is also used in some contexts.

Besides These Benefits, There Are Also

The extrusion of aluminum, which results from the superior properties that aluminum possesses, offers a greater number of benefits than a variety of other processes and materials do. These advantages can be attributed to the superior properties that aluminum possesses.

Shoulder comfort and relaxation are ensured at all times.

- First, Aluminum extrusions are lighter in weight than steel and iron, and the weight of aluminum is one-third of the weight of steel and iron combined

- Aluminum also has a higher strength-to-weight ratio than steel and iron

- Aluminum also outperforms iron and steel when compared in terms of its strength to weight ratio

- Because of this, aluminum is much easier to manipulate and transport, which makes it a more appealing material to buy in circumstances in which reducing weight and lowering transportation costs are primary concerns

- Aluminum can also be manipulated and transported without the need for any special tools or equipment

- It is possible to concentrate the strength exactly where it is required by adjusting the thickness of the wall and incorporating internal reinforcement into the tooling die

- This makes it possible to concentrate the strength precisely where it is needed

- Because of this, the strength will be able to be distributed uniformly

- Aluminum extrusions that are flexible are able to withstand the load, bend while it is being applied, and even spring back to their original shape after being subjected to the shock

- This ability allows them to be used in a variety of applications

- Because of these capabilities, they are able to be utilized in a wide variety of contexts

- The process of recycling aluminum can take place in a variety of different ways

There are a variety of profiles, each of which can be classified differently.

Extrusion profiles made of aluminum can be purchased in a large number of unique configurations, each of which is entirely dependent on the applications that are designed to make use of the particular profile. These configurations can be found in a variety of different sizes and shapes. Profiles, which are capable of having a wide variety of thicknesses applied to them, can have this particular thickness applied to them. Nevertheless, the fact that it can be obtained at a low cost is perhaps the most significant benefit of aluminum, and it is possible that this is the case.

Types of aluminium profiles are possible to see through the crosspiece, revealing that the interior is hollow. It is standard practice to make use of beams that are hollow on the interior when constructing the framework for buildings, bridges, and other types of structures. This is because hollow beams allow for more efficient use of materials. They accomplish a goal that is analogous to the one that is served by the hollow beams, with the primary difference being that square beams are able to provide support that is not only more resilient than the hollow beams, but that is also more consistent. It's possible to consider the load bearings on the walls and the pillar supports as both making use of square profiles in some capacity. The manufacturing process is what determines whether square profiles are seamless or non-seamless, and this distinction is based on how the profiles are constructed. Non-seamless square profiles are constructed differently than seamless square profiles. It is necessary to do this in order to make the interior of the profile more uniform, so this is why it is done. Because of its malleability, low weight, and resistance to corrosion, aluminum is an excellent material for use in the framing of windows.

Windows need to be crafted from a high-quality material that is capable of ensuring its longevity because they are exposed to harsh environments such as rain, storm, sun, humidity, and dust, amongst other things. This makes it necessary for windows to be made from a material that is capable of meeting these requirements. Because of this, it is necessary to make use of a substance that is competent enough to fulfill these prerequisites.

In addition, there are some low-rise buildings that are appropriate candidates for the installation of RCW profiles.

RCW profiles do not offer any function that is related to the structure; rather, their primary function is to act as a barrier to prevent environmental elements such as dust and rain from entering the building. RCW profiles do not offer any function that is related to the structure. RCW profiles do not provide any function that is connected to the structure of the building. These door sections are also sometimes known as ED sections in the industry. These kinds of doors are located in a wide range of establishments, including retail shops, restaurants, and other businesses. They can be found in a variety of settings. In addition to this, they are able to stop the glass from completely falling onto the other side of the table. A building's louvers, which are also referred to as louvres, create a passageway that allows natural light and air to enter and exit the structure. Louvres are another name for louvers. They are responsible for preventing debris from entering the building premises, which is another important function that they perform, making this yet another one of the many important roles that they play.

T sections are a specific kind of product that can incorporate many different kinds of components. Some examples of the kinds of products that are included in this category are horizontal flanges and vertical webs. T sections are also a type of product. This particular kind of profile is assembled in such a way that it is versatile enough to be used not only in corners but also as a component in truss networks. This adaptability allows it to be used in both of these applications. The process of attaching different kinds of aluminum profiles to it, such as square or hollow beam profiles, is quite straightforward and uncomplicated, and it can be carried out with relative ease. In addition, fittings are fastened to the T-section so as to raise the total amount of support and, as a consequence, the structure's ability to withstand the passage of time.

shiyue1108yiyi shiyue1108yiyi 2 anos atrás

Dear immortals, I need some inspiration to create https://www.wowtot.com