The subtle brilliance of Optical Brightener for Plastic combined with the effectiveness of Fluorescent Whitener has transformed how manufacturers achieve clarity and whiteness in polymers. These compounds, though used in minute quantities, create a remarkable visual improvement in plastics by converting invisible ultraviolet light into visible blue light, neutralizing yellowish tones, and providing a cleaner, brighter look.

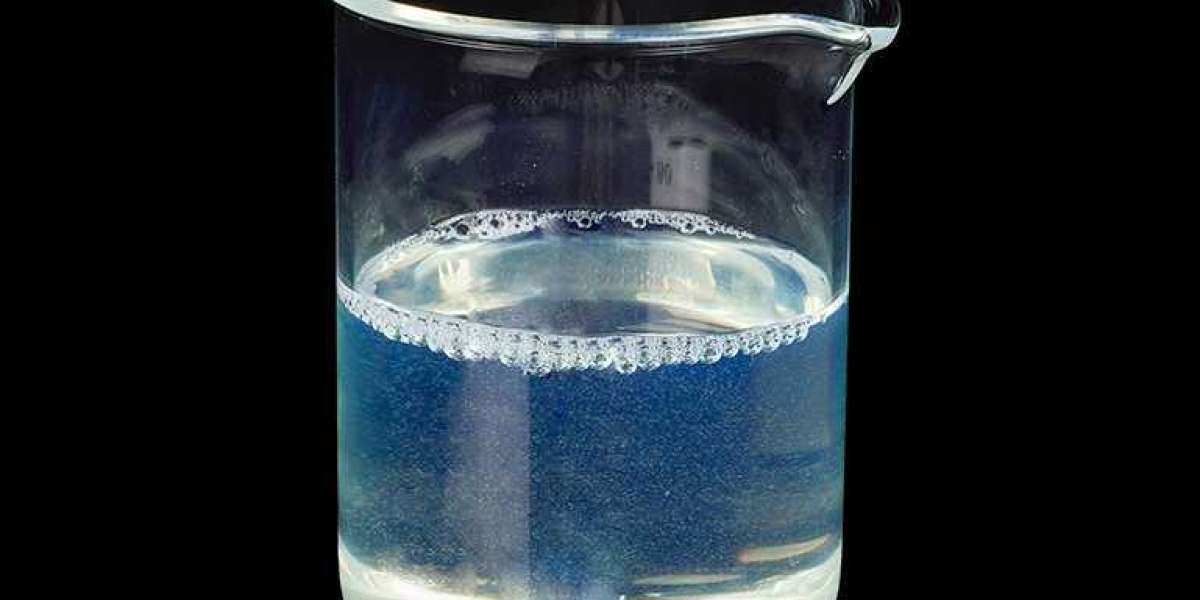

The science behind this transformation lies in photoluminescence. When ultraviolet rays strike the surface of treated plastic, the optical brightener absorbs and re-emits light at a slightly different wavelength. This optical effect doesn’t actually add pigment but alters perception, making the material appear purer and more refined. Fluorescent Whitener works similarly, often blended during compounding or masterbatch preparation to ensure uniform dispersion throughout the plastic matrix.

These additives are widely used in polypropylene, polystyrene, PVC, and engineering plastics. The result is a balanced appearance without altering the mechanical or chemical stability of the product. For manufacturers producing packaging films, containers, or molded items, this subtle optical adjustment enhances market appeal and product quality without additional cost burden.

Crafting the right formulation demands precision. Too much brightener can lead to over-fluorescence, causing a bluish or unnatural hue. Too little, and the yellowish tint remains. Technicians adjust dosage according to resin type, processing temperature, and desired brightness level. Modern Optical Brightener for Plastic products are heat-stable, ensuring consistent color even under high extrusion or molding conditions.

Applications extend beyond visual enhancement. Optical brighteners also protect against UV degradation, prolonging the material’s lifespan. By reflecting a portion of ultraviolet energy, they slow down photo-oxidative reactions, maintaining surface gloss and preventing yellowing over time. This makes them valuable for both indoor and outdoor applications, including consumer goods, electrical housings, and automotive interiors.